Standard Work by Definition

When it come to discussing Lean and the tools we use to implement our Future State Plans, standard work is the easiest to explain and the hardest to complete.

Standard Work is having documented visual processes for every task that is done inside a factory; this includes not only the value adding steps to get the product out of the door, in also includes how the rubbish bins are emptied, when meetings are held, who changes the light bulbs and all of the little tasks that are performed through out each shift.

The Importance of Standard Work

The importance of standard work can’t be overemphasised; having documented processes for everything you do makes training easier. It allows everyone to understand what is expected regarding quality and output. It makes improving a process easier as you know that each operator is doing the task the same way.

Top Level Detail

The value steam map we create can be our top level of standard work; this explains how the product moves through each process and the controls between these processes. For companies with multiple value streams passing through Production, the challenge here is to align each value stream map to check capacity of individual machines. If problems arise creating a bottle neck, the way the work is realised at the start of the process needs reviewing and how the bottlenecked process communicates back to this point.

General Detail

The next level of standard work explains to the operators how an area works; where does the work come from? Where does it go? How do I know if I’m going well? Who do I call if I’m not going well? This level isn’t needed for continuous production. It is vitally important when the manufacturing process is complex and FIFO lanes or supermarkets are being used to control the work flow through the factory. The aim at this level is to keep the standard work simple and visual.

Granular Detail

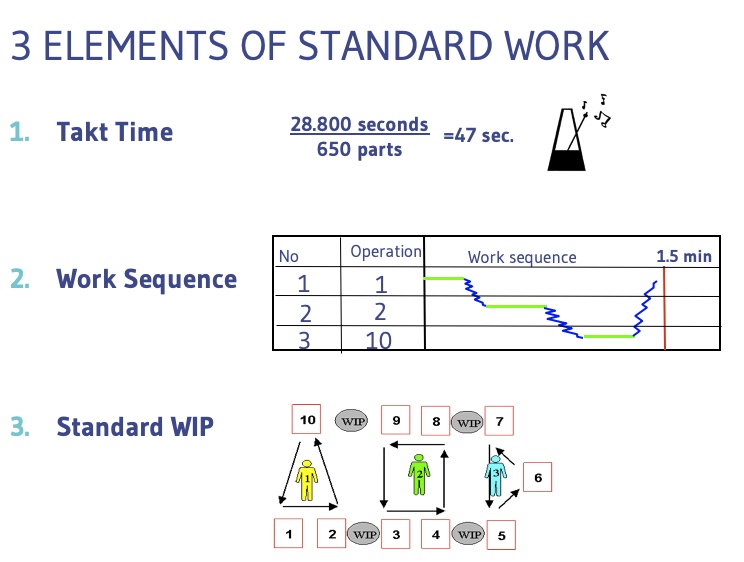

This detailed level of standard work is where the real gains are in improving manufacturing efficiency (but of course the other levels are need as well). The more repeatable the process the easier it is to define the work standards. Agreement across operators and shifts is vital. This creates the consistency that can then be improved by all the team members.

For companies that have a large range of products and value streams creating standard work is harder, but not impossible. Here we start with the product families or groups that were defined in the initial stages of Lean implementation when evaluating where to begin with creating the first value stream map. Again, our aim here is for the standard work documents to be simple and visual, aligning with the visual controls in the work area.

Conclusion

Finding good examples of standard work is challenging; standard work defines the DNA of what a company does and many are reluctant to share this level of detail with others. As with many the Lean tools, standard work is best accomplished by getting your key people together, defining a starting point and get started. The details of what the standard work documentation will look like can be refined as the underlying information is gathered through direct observation of production, reviewed with operators and key support people and refined.

Standard work will be the hardest part of implementing your future state Lean Program, but also the most rewarding.