Collecting Value Stream Map elements

When getting started on your lean journey, it is exciting and understandable that you want to jump ahead and start creating factory layouts before you fully understand your current customer requirements and current manufacturing processes. However we need to gather as much data and current procedures as there are available, so we can fully understanding the key elements in the process.

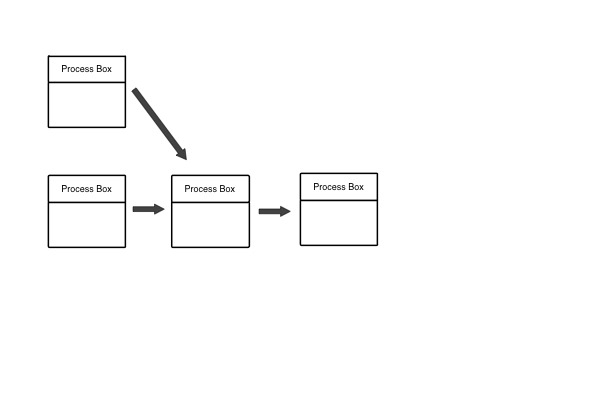

This is important because we need to create a baseline to document the current state so that the future state is actually better and improves the baseline. We often discover together that our assumptions are not always correct once we begin to observe our processes and collect data in detail. When creating a value stream map it is often a struggle to get down on paper all the required tasks or process box. As we have outlined above, it is a critical step when starting with your lean journey.

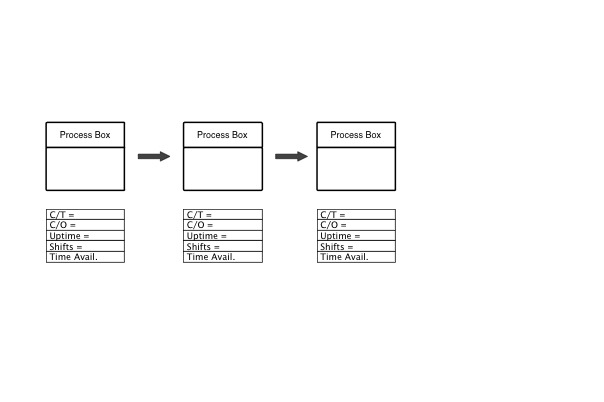

At this time it is important to collect all relevant data can support the development of what a future state might be. Under each process box there is a data box that contains observable facts around each process step. Ideally these facts would be validated as the current manufacturing performance data., with your manufacturing team.

To get started here is a list of typical data that we look for including into this data box.

C/T = Cycle Time – How often a part is completed by the process

L/T = Lead time – The total time for one piece to move across the Value Stream from start to finish

C/O= Change over – Switch time for one product type to another

UpTime = % of available hours

Number of Operators

Number for shifts

Batch size

ScrapRate ( if known)

Here we have highlighted the importance of gathering good data when creating your initial current state value stream map. The challenge is to pause and collect the data at this step and to it properly; skipping ahead may lead to rework and slow down the implementation process overall.