Quality in a Lean Manufacturing Organisation

Quality? What Does it Mean?

These days “Quality” in a manufacturing organisation has so many meanings; there are Quality Management Systems, Quality Managers, statistical process controls and some of us even remember the good old “Quality Circles”. With the focus in manufacturing turning from Quality to Lean, where does Quality fit now?

Quality is still needed in every manufacturing environment and “Quality at source” is fundamental to a flowing production system. Quality at source builds the quality requirements into each step of the process and has controls so known problems are highlighted and not passed on. As a Lean improvement system is reducing the wastes in the production system, wasted materials and time due to poor quality needs attention.

Having Inspectors at the end of a line is no longer an acceptable way to try and control the quality of your product leaving your factory. At each step of the process the product specifications and tolerances need to be known and checked they are correct, at each “value adding” step of the product that changes it’s form, fit or function. these checks need to be built into the process and the quality requirements clearly defined: At this step, I check the length of the section, or the weld quality or the surface finish. If it’s good, it goes here, if it’s not, then what happens also needs to be clearly defined.

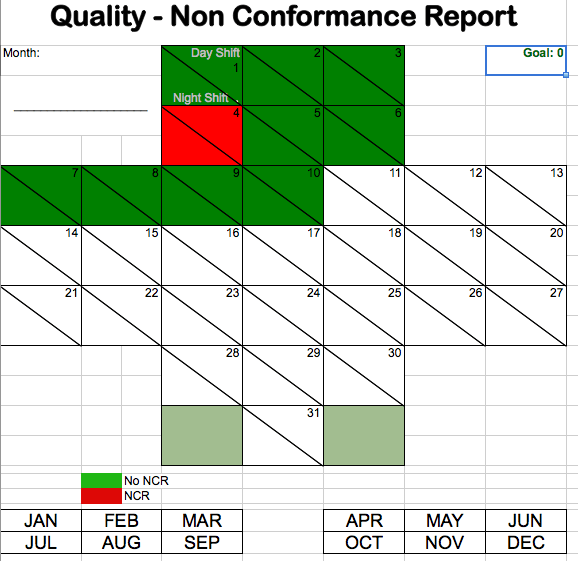

Visual management tools and error proofing are great ways to clearly define the quality aspects that are important at each step and make it easy to determine if the part is acceptable or needs attention. Simple visual templates allow for quick reference to quality performance in a given area. See image below

Statistical process controls (SPC) is only needed on processes where the variability of a process is influencing the final level of quality. While the noble practices of black and green belt six sigma projects will tackle these issue.

The key to success in implementing Quality principles in any organisation is to foster a culture of continuous improvement where there is a focus on quality, lean thinking, and customer satisfaction as the organisation’s one goal.